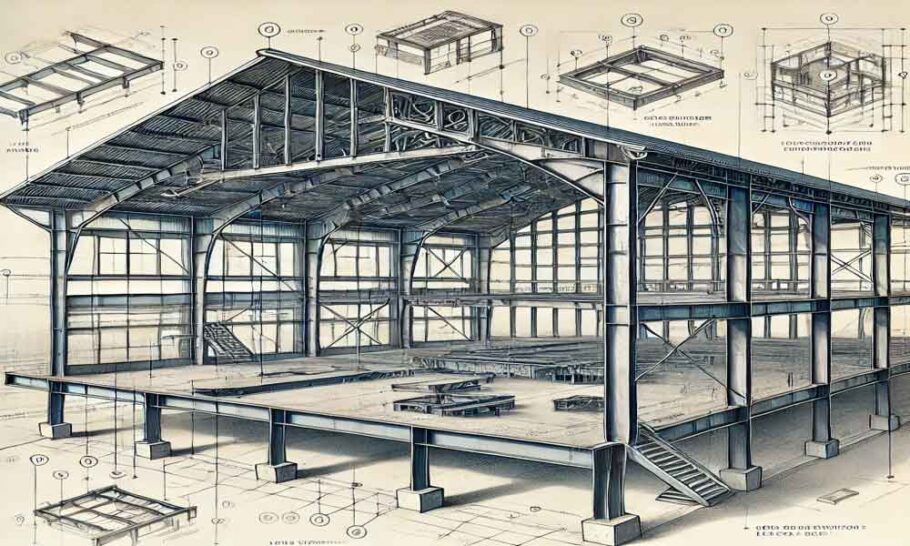

When you’re designing and building a barndominium, one of the most critical components isn’t the steel frame, the siding, or even the roof—it’s the foundation slab. Your barndominium slab isn’t just a flat piece of concrete you walk on; it’s the structural base that supports everything from walls and columns to heavy vehicles and equipment inside your home-shop combination. The strength and durability of that slab depend largely on the load-bearing capacity of the concrete mix you choose.

Understanding how different concrete mixes perform under stress is essential for both cost-effectiveness and long-term safety. Let’s break down what you need to know about concrete mix design, strength ratings, and the specific choices that will make sense for your barndominium.

Why Load-Bearing Capacity Matters in Barndominiums

Barndominiums differ from conventional homes in that they often combine residential and workshop uses. You might be parking a truck, tractor, or even heavy fabrication equipment inside. That means the slab isn’t just bearing the load of household furniture—it’s carrying concentrated and dynamic loads that can exceed those of a typical home garage.

A slab that is too weak can lead to:

- Cracking and settlement under the weight of heavy equipment.

- Uneven floors, making future modifications harder.

- Water intrusion issues if cracks widen.

- Reduced lifespan of the entire structure.

Choosing the right concrete mix ensures your slab can handle these loads without premature failure.

Basics of Concrete Mix Design

Concrete is made from four primary ingredients:

- Cement – The binder that holds everything together.

- Aggregates – Sand, gravel, or crushed stone that provide bulk and strength.

- Water – Activates the cement and drives hydration reactions.

- Admixtures – Optional chemicals to enhance properties (e.g., accelerators, retarders, plasticizers).

The water-to-cement ratio (w/c ratio) is the single biggest factor affecting strength. Lower ratios usually mean higher strength but reduced workability, while higher ratios make the mix easier to pour but weaker.

Understanding Concrete Strength Ratings

Concrete’s compressive strength is measured in pounds per square inch (psi) after 28 days of curing. Common grades include:

- 2,500 psi (17 MPa): Entry-level strength, often used for sidewalks and patios.

- 3,000–3,500 psi (21–24 MPa): Suitable for residential slabs with light loads.

- 4,000 psi (28 MPa): Common for driveways, garage floors, and barndominiums with vehicles.

- 5,000 psi and above (35 MPa+): Heavy-duty industrial slabs, warehouses, or areas subject to high dynamic loads.

For barndominiums, the most common recommendation is 3,500–4,000 psi concrete depending on soil conditions, slab thickness, and expected live loads.

Comparing Different Concrete Mixes for Barndominiums

Let’s look at how common mixes compare in real-world applications:

- 2,500 psi Mix

- Typical Use: Sidewalks, non-load-bearing applications.

- Load Capacity: Around 1,000–1,500 pounds per square foot (psf).

- Suitability: Not recommended for barndominiums. Too weak for heavy vehicles or long-term stability.

- 3,000 psi Mix

- Typical Use: Light residential floors and driveways.

- Load Capacity: About 1,500–2,000 psf.

- Suitability: Could be used for a barndominium slab if loads are limited to residential furniture and light cars. However, it’s not ideal if you plan to store heavy equipment.

- 3,500 psi Mix

- Typical Use: Garage floors, standard house slabs.

- Load Capacity: 2,000–3,000 psf.

- Suitability: This is often the minimum recommended strength for a barndominium. Works well for most light-to-medium duty applications.

- 4,000 psi Mix

- Typical Use: Driveways for trucks, light industrial use.

- Load Capacity: 3,000–4,000 psf.

- Suitability: The most common choice for barndominiums. It balances strength and cost, providing durability for vehicles, shop equipment, and long-term performance.

- 5,000+ psi Mix

- Typical Use: Industrial floors, high-traffic commercial slabs.

- Load Capacity: 4,000–6,000+ psf.

- Suitability: Overkill for most barndominiums unless you’re running a machine shop or expecting very heavy static loads. More expensive but extremely durable.

Other Factors That Affect Load-Bearing Capacity

The strength of the concrete mix is important, but it’s not the only factor determining slab performance. Your slab’s ability to carry loads depends on a combination of:

- Slab Thickness

- A 4-inch slab with 3,000 psi concrete won’t perform as well as a 6-inch slab with the same mix.

- For barndominiums, 4″ is the bare minimum, while 5–6″ is strongly recommended.

- Reinforcement

- Rebar or welded wire mesh helps distribute loads and control cracking.

- A barndominium slab should always include reinforcement, not just plain concrete.

- Subgrade Preparation

- Compacted soil and a gravel base are critical to prevent slab settling.

- Even strong concrete will crack if poured over poorly prepared soil.

- Curing Process

- Concrete reaches its rated strength after 28 days, but proper curing (keeping it moist and at stable temperatures) is vital for reaching its full potential.

- Load Distribution

- Point loads (e.g., jack stands, heavy safes, or columns) stress a slab differently than evenly distributed loads (like cars parked on four wheels).

- Special reinforcement may be needed under columns or equipment pads.

Real-World Examples

- Barndominium with a Home + Garage Setup: A 4,000 psi mix at 6 inches thick with rebar reinforcement will comfortably handle trucks and workshop equipment.

- Light Residential Barndominium: A 3,500 psi mix at 5 inches thick may be sufficient if only used for furniture and light vehicles.

- Barndominium with Workshop for Heavy Equipment: A 5,000 psi mix with 6–8 inch slab thickness and heavy reinforcement ensures long-term durability under dynamic and static loads.

Cost Considerations

Concrete mix strength directly impacts cost. On average:

- Each jump of 500 psi in strength adds $5–$15 per cubic yard.

- Since a typical barndominium slab may require 40–100 cubic yards of concrete, moving from 3,500 psi to 4,000 psi could add $500–$1,500 to the project.

- However, compared to the cost of repairing a cracked slab later, this is often a worthwhile investment.

Recommendations for Your Barndominium Slab

- Minimum: 3,500 psi with 5-inch thickness and reinforcement.

- Preferred: 4,000 psi with 6-inch thickness, rebar reinforcement, and proper subgrade preparation.

- Heavy-Duty Applications: 5,000 psi with 6–8 inches of thickness, reinforced with #4 or #5 rebar in a grid pattern.

Conclusion

The load-bearing capacity of your barndominium slab depends on much more than just pouring concrete. The mix you choose, combined with slab thickness, reinforcement, and preparation, will determine how well your foundation stands the test of time. While 3,500 psi concrete may work for lighter uses, most barndominium builders opt for 4,000 psi for a balance of strength, durability, and cost. If your barndominium doubles as a heavy workshop, don’t hesitate to go even stronger.

Think of the slab as an investment in your barndominium’s future. It’s far cheaper to build it strong the first time than to deal with cracks, failures, and costly repairs later on.